Providing a Variety of Technical Services for Your Specialized Needs

Corrosion Research

Our facility features numerous specialized custom-made autoclaves designed to simulate corrosive environments. Capable of high pressures (up to 10,000 psi) and temperatures (up to 900°F) with pressurized gases such as H2S, CO2, and CH4, as well as various liquids, our rotary agitated autoclaves mix contents under controlled conditions.

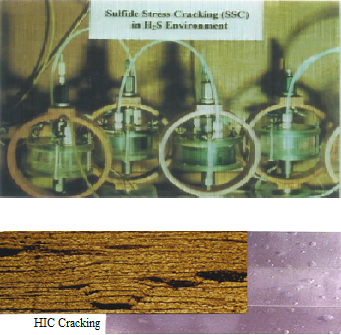

Testing of Steel for Wet H2S Services

The evaluation of steels for wet H2S services is routinely performed for steel mills, pipeline and refining industries, and pressure vessel fabricators. Corrmet has been selected by the oil and gas industry to perform full-scale tests evaluating the HIC resistance of plate steels for pressure vessels, pipeline steels, and forged steel fittings.

Testing includes:

- Hydrogen Induced Cracking (HIC) per NACE TM0284-96 in synthetic sea water or TMO177 solution

- Sulfide Stress Cracking (SSC) per NACE TM0177-96 – including tensile, bend beam, C-ring, and SOHIC tests

- SSC testing per ASTM G-39 (bent-beam stress-corrosion) using TM0284 or TM0177 solutions

- Elastomer Compatibility Tests (API, ASTM, NACE)

Inhibitor Evaluation

Our inhibitor evaluation program features low temperature wheel tests and high temperature/high pressure wheel tests (500°F, 10,000 psi). We assess static and dynamic thermal stability, solubility, emulsification, acid inhibitor performance, and conduct side stream (on-site) testing. In addition, electrochemical techniques are used to study inhibitor performance, while high pressure/high temperature electrochemical studies of chemicals, alloy corrosion resistance, and coating performance are performed using several rotating autoclaves to simulate velocity effects and erosion corrosion.